-

Новости

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Статьи пользователей

-

Offers

-

Jobs

-

Courses

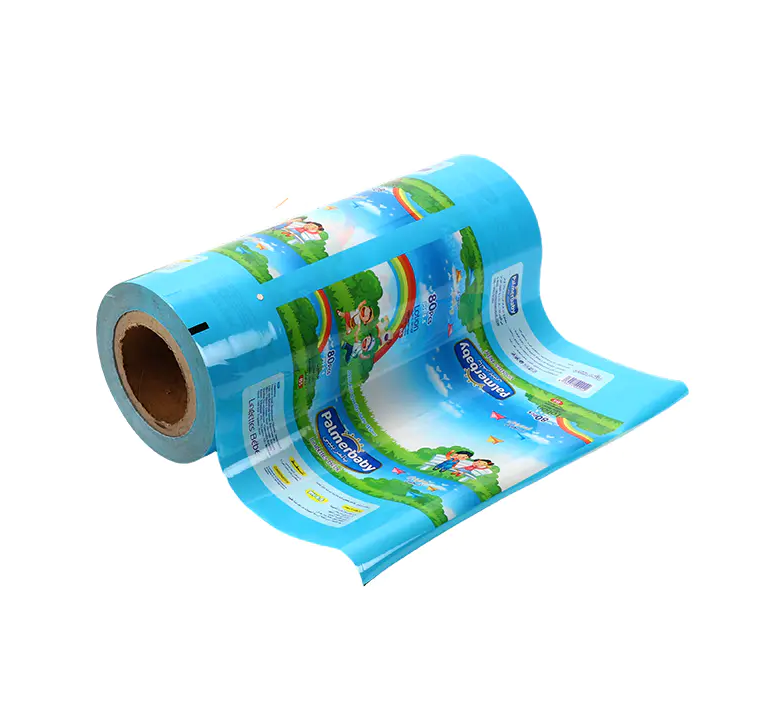

Food Packaging Film Roll and Sustainable Packaging Practices

Food packaging film roll plays an essential role in modern food distribution systems, supporting both product protection and efficient handling. From fresh produce to processed snacks, many food categories rely on flexible films to maintain quality during storage and transportation. A Food packaging film roll is designed to provide a balance between durability, clarity, and sealing performance, making it suitable for automated packing lines and manual operations alike.

One of the main functions of a Food packaging film roll is to act as a barrier against moisture, air, and external contaminants. These films help slow down oxidation and dehydration, which are common factors affecting shelf life. In frozen and refrigerated environments, packaging film supports temperature stability and reduces surface frost or moisture accumulation. For dry goods, the same material prevents humidity absorption that could compromise texture or flavor.

Material selection remains an important consideration in Food packaging film roll production. Common options include polyethylene, polypropylene, and multilayer composite structures. Each material offers specific properties related to flexibility, tensile strength, and heat sealing behavior. Some films are engineered for transparency to allow product visibility, while others focus on opacity to protect light-sensitive foods. This diversity allows manufacturers to choose a film structure aligned with the intended food application.

Processing methods also influence the performance of a Food packaging film roll. Blown film and cast film technologies create different surface characteristics and thickness consistency. Uniform thickness contributes to stable sealing and reduces the risk of tearing during high-speed packaging. Surface treatment may be applied to improve print adhesion, allowing clear labeling and branding information to remain legible throughout the product lifecycle.

Another advantage of using a Food packaging film roll is adaptability across multiple packaging formats. The same roll can be converted into pouches, flow wraps, sachets, or lidding films depending on equipment configuration. This flexibility supports production efficiency, especially in facilities handling diverse product lines. Film rolls are also compatible with various sealing methods, including heat sealing and pressure-based closure systems.

Sustainability considerations are increasingly shaping the development of Food packaging film roll solutions. Film downgauging, which reduces material thickness without sacrificing strength, helps lower material consumption. Water-based inks and solvent reduction techniques are being adopted to minimize environmental impact during printing and conversion.

Quality control is another factor influencing Food packaging film roll performance. Roll tension, edge alignment, and winding consistency affect how smoothly the film runs on packaging machines. Poor winding can lead to stoppages or material waste. Manufacturers typically test films for puncture resistance, seal strength, and elongation to ensure stable operation under varying conditions.

In daily use, Food packaging film roll contributes to food safety and operational reliability. It supports hygienic handling, reduces direct contact, and helps maintain consistent presentation. Ongoing material innovation and process refinement ensure that Food packaging film roll continues to serve as a practical component within food packaging systems worldwide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness