Applications of Inclined Lathes in Modern Manufacturing

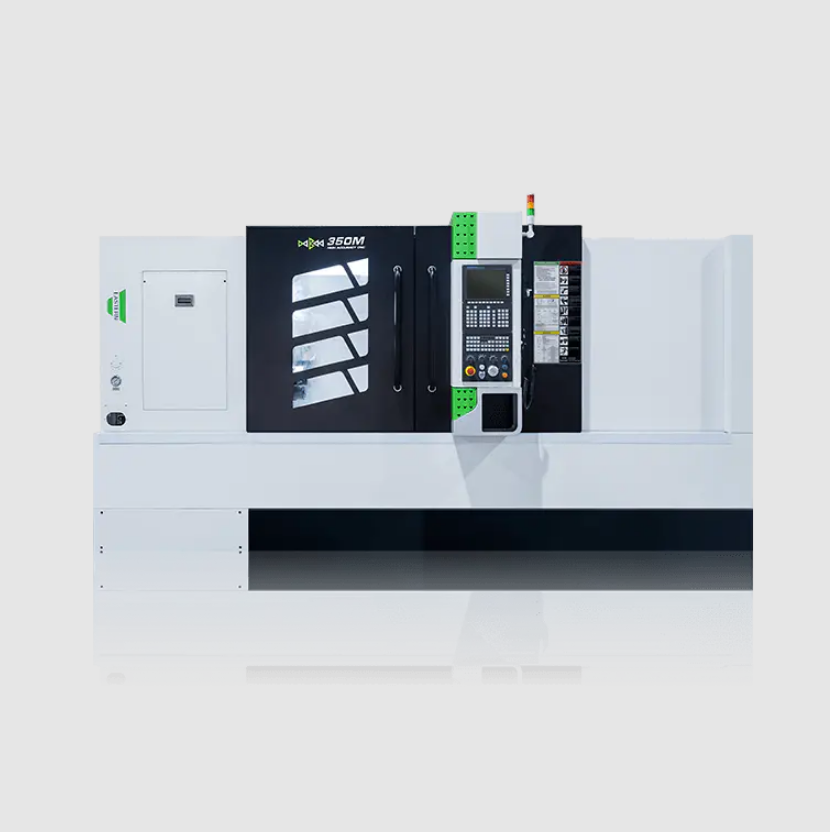

An inclined lathe, also known as a slant bed lathe, is designed with its bed set at an angle, usually between 30 and 45 degrees. This configuration helps improve chip evacuation because gravity naturally directs chips away from the cutting area. Operators also benefit from better visibility and easier maintenance due to the slanted structure.

The inclined design enhances rigidity, as cutting forces are distributed more evenly across the angled bed. This stability supports accurate machining while reducing vibration during operations. The carriage and turret are mounted on the slant, which allows for smooth movement and consistent tool positioning. Linear guideways are often used in this type of machine, reducing friction and enabling higher feed speeds.

Inclined lathes are suitable for producing parts that demand accuracy and repeatable quality. They are often equipped with additional functions, such as sub-spindles or live tooling, which expand their capabilities beyond simple turning. By integrating these options, a single machine can perform multiple operations without requiring additional setups.

In manufacturing environments, inclined lathes are applied to various industries where medium-sized components are processed. Their layout, efficiency, and adaptability make them a reliable choice for modern machining needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness