High and Low Temperature Durability Explained

Importance of Temperature Resistance in Plastic Trays

In modern logistics and industrial storage, plastic trays are often exposed to extreme temperature conditions. From cold-chain transportation to high-temperature manufacturing environments, thermal resistance plays a decisive role in determining service life and safety. A Double-faced Grid Plastic Tray is commonly used in demanding applications, making its performance under both high and low temperatures a key concern for buyers and operators. Understanding how temperature affects structural stability helps ensure reliable long-term use.

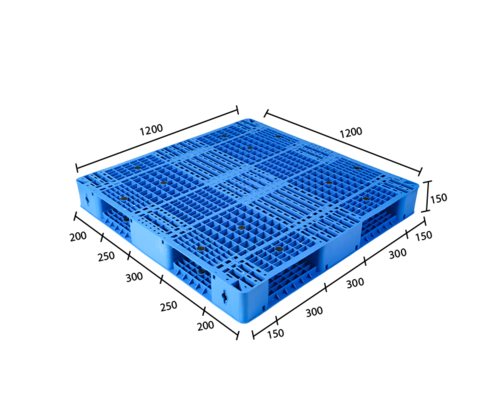

Structural Characteristics of Double-Faced Grid Design

The double-faced grid structure creates a symmetrical reinforcement pattern on both sides of the tray. This balanced design improves load distribution and reduces localized stress, which is particularly important when temperature changes cause material expansion or contraction. By maintaining structural equilibrium, the grid design helps the tray resist warping, bending, or twisting that can occur under thermal stress.

Performance in High-Temperature Environments

At elevated temperatures, plastic materials tend to soften, which can reduce stiffness and load-bearing capacity. A well-designed tray compensates for this behavior by incorporating deeper grid ribs and adequate wall thickness. These structural features help maintain rigidity even when the material becomes more flexible. In industrial settings where trays may be exposed to warm warehouses, production lines, or sun-heated transport vehicles, thermal stability ensures that the tray retains its shape and functional reliability.

Resistance to Low-Temperature Brittleness

Low-temperature environments present a different challenge, as plastic materials can become brittle and more susceptible to cracking. Cold storage facilities and refrigerated logistics require trays that maintain impact resistance even below freezing. The grid structure of a Double-faced Grid Plastic Tray helps absorb mechanical shock by distributing impact forces across multiple reinforcement points. This design reduces the likelihood of sudden fractures when trays are handled or stacked in cold conditions.

Material Behavior Under Thermal Cycling

Repeated exposure to alternating high and low temperatures can accelerate material fatigue. Thermal cycling causes expansion and contraction that gradually weaken structural bonds if not properly managed. Balanced grid reinforcement minimizes internal stress buildup, allowing the tray to adapt to temperature changes without developing cracks or permanent deformation. Over time, this contributes to consistent performance across a wide temperature range.

Influence of Load Conditions at Extreme Temperatures

Temperature resistance cannot be evaluated independently of load conditions. High loads combined with elevated temperatures may increase deformation risk, while heavy loads in cold environments can amplify brittleness-related failures. The grid-reinforced double-faced design helps mitigate these risks by maintaining uniform load transfer regardless of temperature. This ensures that trays remain stable during stacking and transport, even under challenging thermal conditions.

Environmental Adaptability in Real-World Applications

In real-world use, plastic trays may encounter moisture, temperature fluctuations, and varying handling practices simultaneously. The combination of grid reinforcement and symmetrical structure improves adaptability, allowing the tray to perform consistently across different climates and operational settings. Whether used in cold-chain logistics or industrial production environments, temperature-resistant design enhances reliability and safety.

Long-Term Durability and Service Life

Long-term durability depends on how well a tray maintains its mechanical properties over time. A Double-faced Grid Plastic Tray designed for thermal resistance demonstrates reduced warping, fewer cracks, and consistent load performance after repeated exposure to temperature extremes. This durability lowers replacement frequency and contributes to cost efficiency in high-usage operations.

The ability of a Double-faced Grid Plastic Tray to withstand both high and low temperatures is closely tied to its grid structure, material behavior, and load distribution design. By balancing reinforcement on both faces, the tray resists softening at high temperatures and brittleness at low temperatures. When used within its design limits, it delivers reliable performance across diverse thermal environments, making it a dependable choice for industrial storage and transportation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness