Vulcanizing Resin Performance in Industrial Applications

Importance of Vulcanizing Resin Properties

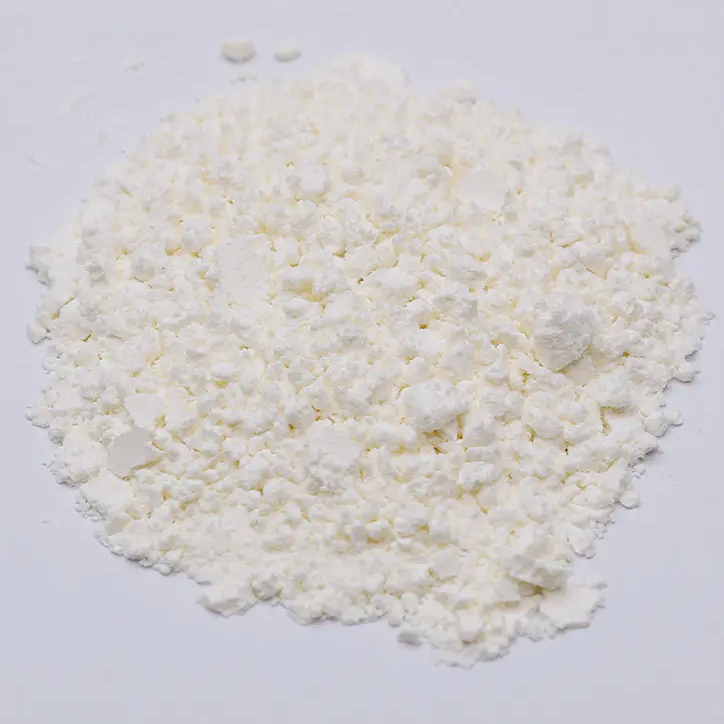

Vulcanizing resin is a critical material in the rubber and polymer industries, providing enhanced mechanical strength, durability, and resistance to deformation. The hardness and mechanical strength of vulcanizing resin determine its suitability for various industrial applications, such as tires, seals, gaskets, and molded components. By understanding these properties, manufacturers can ensure product performance, longevity, and safety. High-quality vulcanizing resin, sourced from a reputable Vulcanizing Resin supplier, is engineered to deliver consistent hardness and strength under a range of conditions.

Understanding Hardness in Vulcanizing Resin

Hardness is a measure of a material’s resistance to indentation or surface deformation. Vulcanizing resin typically exhibits high hardness due to crosslinked polymer structures formed during the curing process. The type and amount of vulcanizing agents, fillers, and additives influence the final hardness. For instance, resins with higher crosslink density demonstrate increased rigidity, which is advantageous for applications requiring dimensional stability under load. Hardness tests, such as Shore A or Shore D, are commonly used to quantify surface resistance and ensure that the resin meets specific application requirements.

Mechanical Strength and Load-Bearing Capacity

Mechanical strength refers to a material’s ability to withstand forces without failure. Vulcanizing resin is designed to endure tensile, compressive, and shear stresses. High mechanical strength is achieved through optimized polymer chains, crosslinking density, and the incorporation of reinforcing fillers. This ensures that the resin can maintain shape and functionality under continuous or dynamic loading. For industrial applications such as conveyor belts, seals, and automotive components, sufficient mechanical strength prevents cracking, tearing, or permanent deformation, contributing to product longevity and reliability.

Factors Affecting Hardness and Strength

Several factors impact the hardness and mechanical performance of vulcanizing resin. Curing time and temperature directly influence crosslink density, while the type of fillers and additives can either reinforce or plasticize the material. Over-curing may result in excessive brittleness, reducing impact resistance, while under-curing can leave the resin too soft, compromising load-bearing capabilities. The balance between hardness and flexibility is crucial to achieve optimal performance for specific applications.

Testing and Quality Assurance

To ensure that vulcanizing resin meets performance standards, manufacturers conduct rigorous testing. Hardness measurements and mechanical tests, such as tensile and compression tests, evaluate whether the material can withstand operational stresses. Consistent quality is critical, especially in safety-sensitive applications like automotive parts, industrial seals, or high-pressure gaskets. Sourcing resin from a reliable Vulcanizing Resin supplier ensures compliance with quality standards and minimizes variability across production batches.

Ensuring High-Performance Vulcanizing Resin

The hardness and mechanical strength of vulcanizing resin are vital characteristics that determine its industrial applicability and reliability. High crosslink density, appropriate additives, and precise curing conditions are key factors in achieving the desired balance of rigidity and flexibility. By understanding these properties and conducting proper quality control, manufacturers can produce durable, high-performance rubber products. Vulcanizing resin remains a cornerstone material for industries requiring components with superior mechanical strength and long-lasting durability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness