A Guide to Choosing Thin Wall Food Container Moulds

Thin wall food container moulds are essential in the production of lightweight, durable, and high-quality food packaging. Choosing the right mould ensures consistent product quality, efficiency, and safety, especially for applications in the food industry.

Material Compatibility

The first factor to consider is the compatibility of the mould with the intended plastic material. Common materials for thin wall food containers include polypropylene (PP) and polyethylene (PE). Ensure the mould is designed to handle the processing temperatures and flow characteristics of these plastics. High-quality steel or aluminum moulds are typically used for durability and precision.

Mould Design and Precision

Design and precision are critical for producing thin wall containers with uniform thickness and smooth surfaces. Look for moulds with optimized gate locations, proper draft angles, and efficient cooling channels. Well-designed moulds reduce the risk of warping, sink marks, and uneven walls, ensuring that the containers maintain their shape and functionality.

Production Volume and Cavity Number

Consider the expected production volume when choosing a mould. Single-cavity moulds are suitable for low-volume production or prototyping, while multi-cavity moulds increase output efficiency for large-scale manufacturing. Multi-cavity designs also help reduce production costs and cycle time while maintaining consistent quality.

Durability and Maintenance

Durability is essential for long-term use. Hardened steel moulds or those with surface treatments resist wear and corrosion. Regular maintenance, including cleaning and inspection, ensures smooth operation and prolongs the mould’s service life.

Selecting a thin wall food container mould involves evaluating material compatibility, design precision, production volume, and durability. Proper selection ensures the efficient production of high-quality, safe, and reliable food containers suitable for various applications.

https://www.food-container-mold.com/product/disposable-plastic-multi-grid-food-container-mould-series/square-four-gid-box-and-4-1-box-lid-thin-mould.html

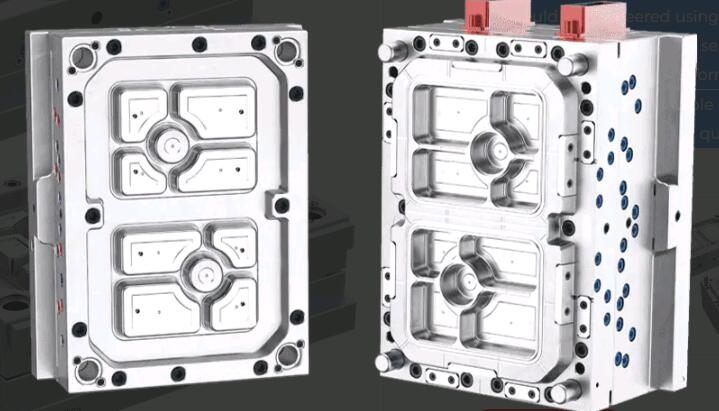

Our Disposable Plastic Disposable Plastic Square Four Grid Box And 4+1 Box & Lid Thin Mould is engineered using cutting-edge technology in high-precision plastic injection molding. This mold series specializes in producing plastic boxes and lids with exceptional sealing performance, ensuring the integrity and freshness of contents. Crafted from durable 2344 material, the product promises longevity and resilience, meeting stringent quality standards.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness