-

Новости

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Статьи пользователей

-

Offers

-

Jobs

-

Courses

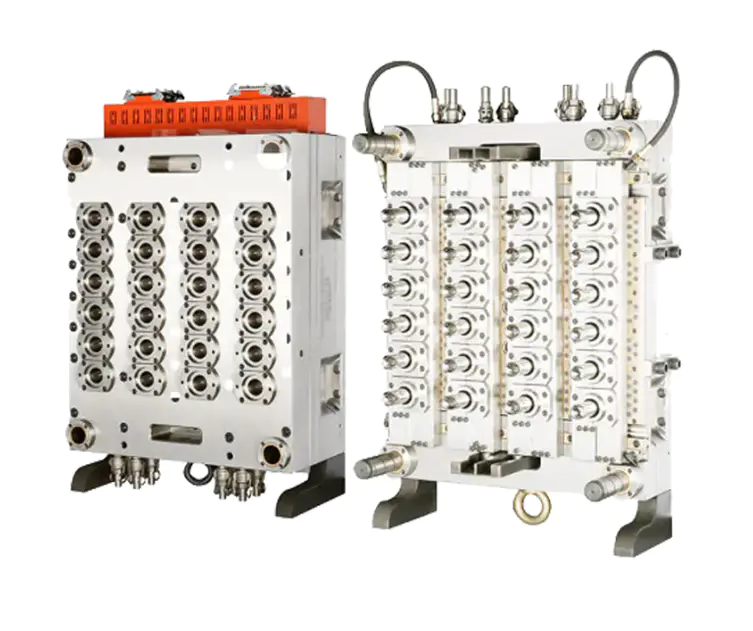

How PET Preform Molds Affect Bottle Strength and Consistency?

PET preform molds are a central component in the production of PET bottles, shaping the preforms that will later be blown into final containers. The accuracy of these molds determines the structural integrity, weight, and appearance of the bottles, making them a key factor in product quality and performance.

During the molding process, PET resin is heated and injected into the preform mold under high pressure. The mold ensures that the preform attains the correct shape, length, and diameter. Even small deviations in mold precision can result in uneven wall thickness, weak points, or air pockets in the preform, all of which can affect the durability of the final bottle.

The materials used in PET preform molds must resist wear and thermal stress. Hardened steel and treated alloys are commonly selected to ensure the mold can withstand repeated use under high temperatures and pressures. Regular inspections and maintenance are essential to prevent defects such as burrs, scratches, or cavity damage, which could affect preform quality.

Mold design affects production efficiency. Preform molds with multiple cavities allow several preforms to be produced simultaneously, increasing output without compromising quality. Uniform molds reduce the likelihood of material waste, improve cycle times, and facilitate smoother transitions to the blow molding stage.

Surface finish and mold design also influence the appearance and functionality of the final bottle. Smooth mold cavities prevent marks or defects on the preform surface, ensuring that bottles maintain a consistent look and perform reliably during filling, capping, and transportation. Some molds include temperature control systems to maintain uniform cooling and reduce internal stress in the preform.

Sustainability considerations are becoming more prominent in mold design. Lightweight preforms produced with accurate molds reduce PET material usage, supporting cost-effective and environmentally conscious production. High-efficiency molds also reduce energy consumption by allowing shorter injection cycles and minimizing waste from defective preforms.

In conclusion, PET preform molds are vital in producing consistent and reliable PET bottles. Their design, material selection, and precision directly influence product performance and production efficiency.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness