Asset Performance Management Market Growth Driven by Industry Modernization

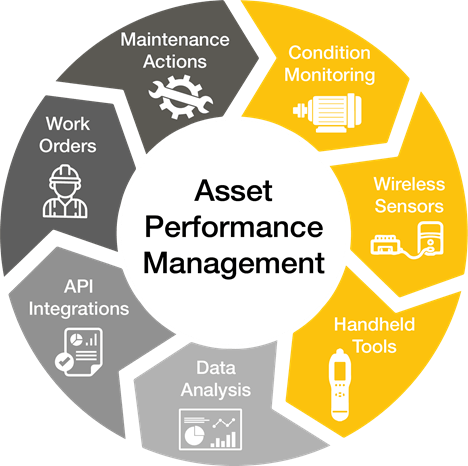

Sustained Asset Performance Management Market Growth continues with projections from USD 4.37 billion to USD 10 billion, maintaining 7.82% CAGR expansion during 2025-2035. Growth catalysts include digital transformation initiatives, operational efficiency demands, and predictive technology advancement. Infrastructure investment globally creates new assets requiring sophisticated performance management from inception. Industry 4.0 adoption necessitates intelligent asset management integrating with smart manufacturing environments. Cloud computing accessibility enables smaller organizations to implement enterprise-grade APM solutions. Artificial intelligence maturation improves predictive accuracy making APM economically viable for broader applications. Workforce demographics shift toward tech-savvy professionals comfortable with analytics-driven maintenance. Sustainability imperatives promote asset lifecycle extension through optimized maintenance over premature replacement.

Growth patterns reveal sector-specific adoption trajectories and implementation approaches. Oil and gas leads growth through complex, high-value assets where failures generate massive costs. Power generation expands APM adoption ensuring grid reliability and regulatory compliance. Manufacturing implements APM supporting just-in-time production and minimal downtime tolerance. Transportation sector grows through fleet management and infrastructure monitoring applications. Water and wastewater utilities adopt APM addressing aging infrastructure and service reliability. Mining operations leverage APM for remote asset monitoring and harsh environment applications. Chemical processing industries implement APM for safety-critical asset management. Building systems integrate APM optimizing facility operations and energy consumption.

Strategic growth enablers focus on adoption acceleration and value maximization. Simplified deployment through cloud platforms and pre-configured industry solutions reduces implementation barriers. ROI demonstration through pilot projects and case studies justifies broader investments. Integration partnerships with ERP and CMMS vendors streamline adoption within existing IT ecosystems. Vendor financing and subscription models improve financial accessibility for capital-constrained organizations. Training programs develop workforce capabilities maximizing solution utilization and value realization. Reference architectures and best practices accelerate successful implementation. Industry associations promote APM adoption through education and standard development. Government incentives for industrial modernization include APM in digital transformation programs.

Growth sustainability requires continuous innovation addressing evolving industrial needs. Emerging technologies including quantum computing and advanced AI promise future capability enhancements. Cybersecurity advancement protects against evolving threats to connected industrial systems. Edge computing evolution addresses latency and bandwidth constraints for real-time applications. Environmental monitoring integration supports sustainability reporting and optimization. Autonomous maintenance systems reduce human intervention in routine decision-making. Industry-specific innovation addresses unique requirements across diverse sectors. Open standards development ensures interoperability and customer choice. Academic partnerships advance research in predictive analytics and maintenance optimization.

Explore Our Latest Trending Reports:

Indoor Farming Technology Market

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness