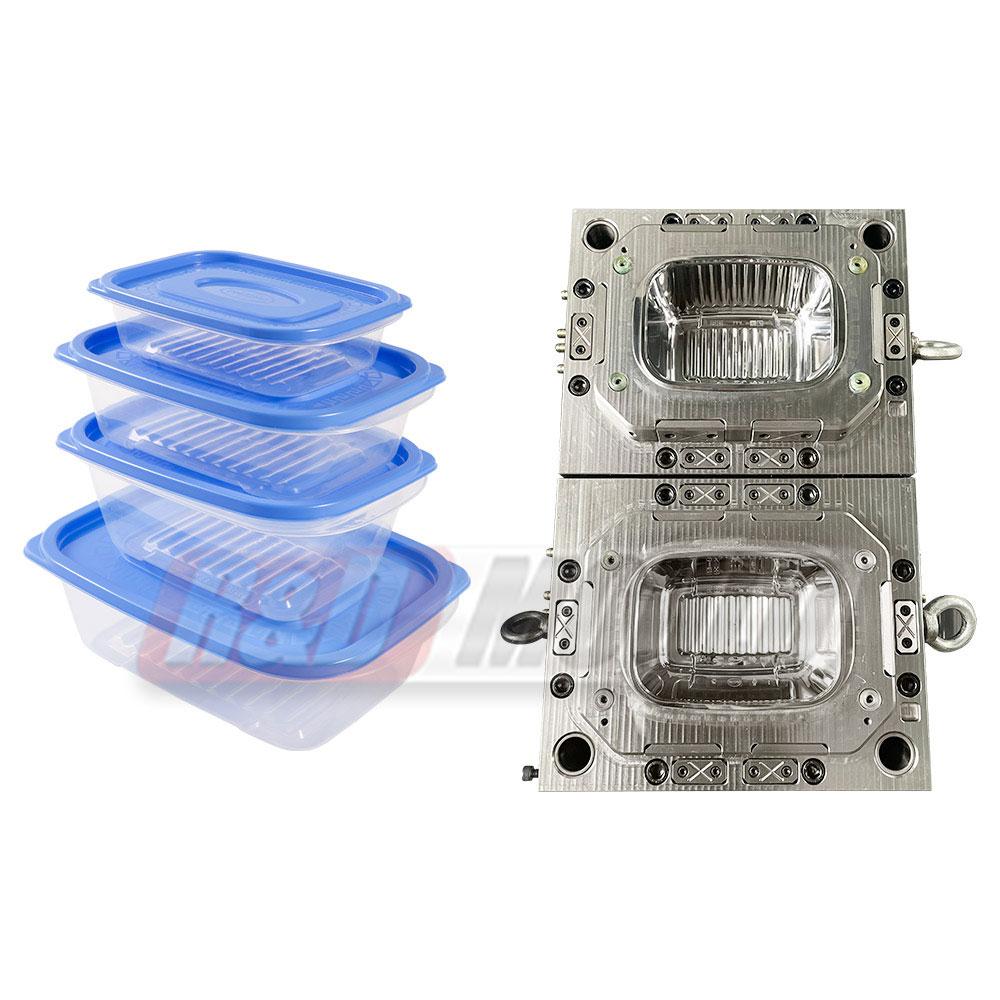

Food Container Mould Solutions That Save Production Time

Food containers are a vital part of modern packaging, especially in the food industry. Plastic food containers have become the many common choice because of their cost-effectiveness and versatility. Thin-wall food containers, in particular, are gaining popularity due to their lightweight design, low production cost, and efficient usability. Choosing the right Food Container Mould is essential for manufacturers who want to maintain consistent quality while meeting diverse packaging needs.

Food Container Mould Manufacturers play a key role in providing solutions that support high-volume production. Professional manufacturers can design and produce moulds that meet specific client requirements, whether it's a lunch box mould, a preserving box mould, or a LOCK&LOCK container mould. The flexibility to create moulds with 1 to 8 cavities allows businesses to scale production efficiently while keeping cycle times low, typically between 20 to 30 seconds.

One question clients often have is about material choice. Food Container Mould Manufacturers usually recommend mould steel based on the desired mould life. The product material is commonly PP or PE, chosen for its durability and compatibility with food storage. great hot runner systems in the moulds reduce flow resistance, improving the quality of each stamped container and minimising production waste.

Another common concern is the durability and functionality of the mould. The right Food Container Mould offers corrosion resistance, impact resistance, and protection against acids, alkalis, and oils. This ensures that the containers maintain their shape and quality throughout mass production. Manufacturers also offer options to produce colourful and varied designs, adding aesthetic appeal without compromising structural integrity.

Clients also want to know how easy it is to use and maintain the moulds. Food Container Moulds are designed to simplify shaping and forming processes, which reduces downtime and increases productivity. Working with experienced Food Container Mould Manufacturers ensures that the mould design supports efficient mass production while minimising technical issues.

Finally, businesses often ask how to choose the right manufacturer. Look for companies with a proven track record in producing diverse mould types and sizes, as well as strong customer support. A reliable manufacturer can provide technical guidance, recommend suitable materials, and deliver a product that meets both production and quality expectations.

Partnering with the right Food Container Mould Manufacturers can make a significant difference in your packaging operations. From reducing cycle times to ensuring consistent container quality, these moulds help businesses stay competitive in a market that increasingly demands lightweight, cost-effective, and functional food packaging.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness