Healthcare Additive Manufacturing Market Size Projected to Reach USD 52.43 Billion by 2032

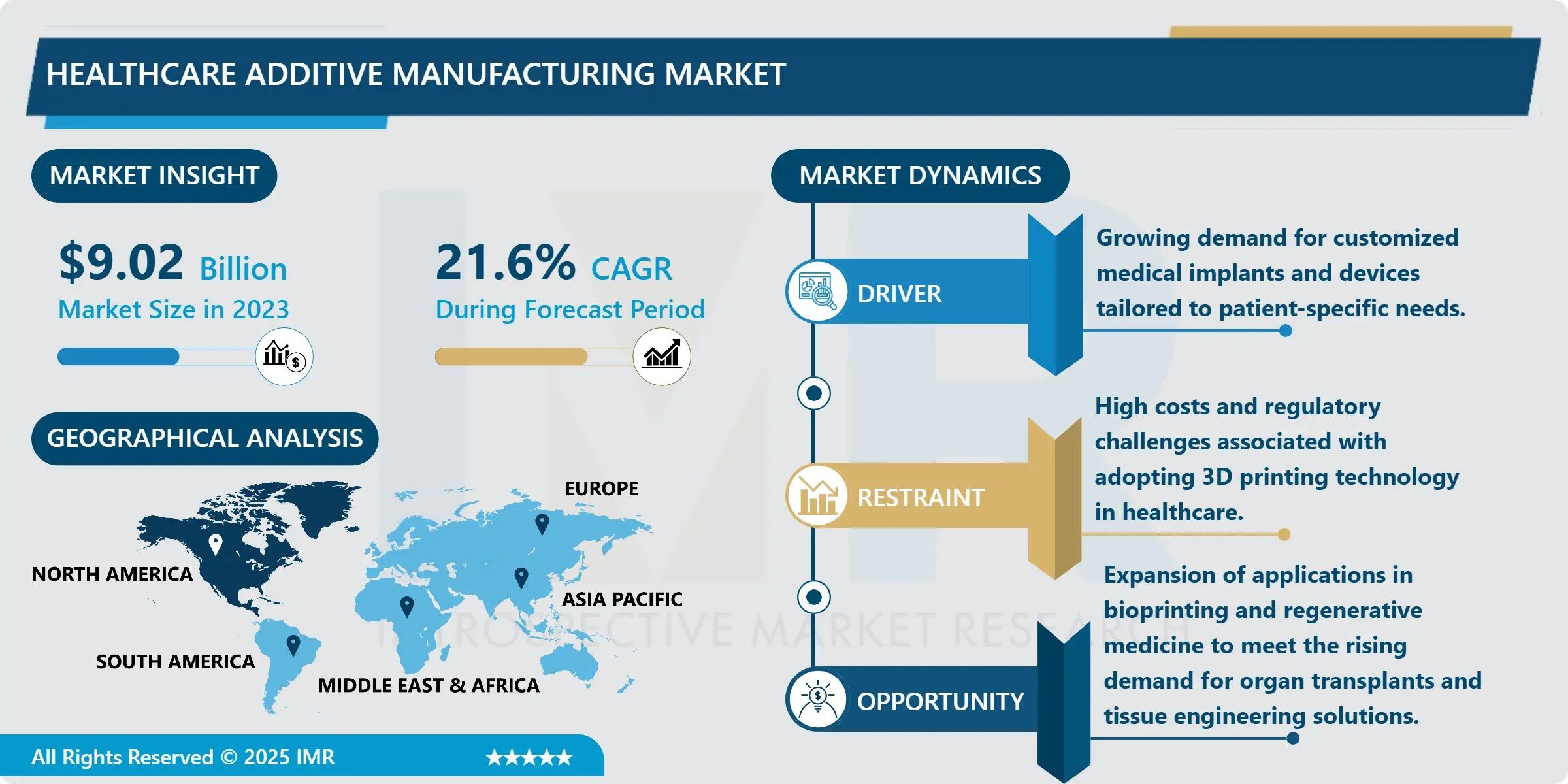

“According to a new report published by Introspective Market Research, Healthcare Additive Manufacturing Market by Technology, Application, and End User, The Global Healthcare Additive Manufacturing Market Size Was Valued at USD 9.02 Billion in 2023 and is Projected to Reach USD 52.43 Billion by 2032, Growing at a CAGR of 21.6% from 2024–2032.”

The Healthcare Additive Manufacturing Market is witnessing rapid expansion as 3D printing technologies increasingly transform the design, development, and production of medical devices, implants, prosthetics, and biopharmaceutical products. Additive manufacturing enables layer-by-layer fabrication of complex, patient-specific components with high precision, reduced material waste, and faster turnaround times compared to conventional manufacturing methods. These advantages make the technology highly suitable for personalized healthcare solutions.

Healthcare additive manufacturing is widely adopted across hospitals, diagnostic centers, medical device companies, and research institutions. Applications range from customized orthopedic and dental implants to surgical instruments, anatomical models, and drug delivery systems. The ability to produce lightweight, complex geometries and biocompatible materials has significantly improved clinical outcomes and surgical planning.

Furthermore, continuous advancements in printing technologies, materials science, and software integration are accelerating adoption across developed and emerging healthcare markets. Supportive regulatory frameworks, rising demand for personalized medicine, and increasing investments in healthcare innovation are collectively driving sustained market growth globally.

Market Segmentation

The Healthcare Additive Manufacturing Market is segmented into Technology, Application, and End User. By Technology, the market is categorized into Stereolithography (SLA), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Electron Beam Melting (EBM), and Others. By Application, the market is categorized into Medical Implants, Prosthetics & Orthotics, Surgical Instruments, Anatomical Models, and Others. By End User, the market is categorized into Hospitals & Clinics, Medical Device Companies, Academic & Research Institutes, and Others.

Growth Driver

The primary growth driver of the Healthcare Additive Manufacturing Market is the rising demand for patient-specific and customized medical solutions. Additive manufacturing allows healthcare providers to design implants, prosthetics, and surgical guides tailored to individual patient anatomy, improving treatment accuracy and outcomes. The growing prevalence of chronic diseases, orthopedic disorders, and age-related conditions has further increased the need for customized medical devices. Additionally, reduced production time and cost efficiency compared to traditional manufacturing methods are encouraging hospitals and medical device manufacturers to increasingly adopt additive manufacturing technologies.

Market Opportunity

A significant market opportunity lies in the expanding use of additive manufacturing for bioprinting and regenerative medicine. The development of 3D-printed tissues, scaffolds, and organ models is opening new possibilities for drug testing, transplantation research, and personalized therapies. As investments in research and development increase and collaborations between healthcare providers and technology companies strengthen, additive manufacturing is expected to play a critical role in the future of advanced medical treatments, creating substantial growth opportunities over the forecast period.

Detailed Segmentation

Healthcare Additive Manufacturing Market, Segmentation

The Healthcare Additive Manufacturing Market is segmented on the basis of Technology, Application, and End User.

Technology

The Technology segment is further classified into Stereolithography (SLA), Fused Deposition Modeling (FDM), and Selective Laser Sintering (SLS). Among these, the Selective Laser Sintering (SLS) sub-segment accounted for the highest market share in 2023. SLS is widely adopted due to its ability to produce highly durable, complex, and accurate components using a wide range of biocompatible materials. Its suitability for manufacturing implants and surgical tools with superior mechanical properties has driven strong adoption across healthcare facilities and medical device manufacturers.

Application

The Application segment is further classified into Medical Implants, Prosthetics & Orthotics, and Anatomical Models. Among these, the Medical Implants sub-segment accounted for the highest market share in 2023. The growing use of 3D-printed orthopedic, dental, and craniofacial implants has significantly contributed to market growth. Additive manufacturing enables precise customization, improved fit, and reduced surgical complications, making it a preferred solution for implant production in modern healthcare settings.

Some of The Leading/Active Market Players Are-

• 3D Systems Corporation (USA)

• Stratasys Ltd. (USA)

• Materialise NV (Belgium)

• GE Additive (USA)

• Renishaw plc (UK)

• EOS GmbH (Germany)

• SLM Solutions Group AG (Germany)

• EnvisionTEC GmbH (Germany)

• HP Inc. (USA)

• Formlabs Inc. (USA)

• Organovo Holdings Inc. (USA)

• Carbon, Inc. (USA)

• Oxford Performance Materials (USA)

• ExOne Company (USA)

• Proto Labs Inc. (USA)

and other active players.

Key Industry Developments

In March 2024, a leading medical device manufacturer expanded its additive manufacturing facility to increase production capacity for 3D-printed orthopedic implants.

The expansion aims to meet rising demand for patient-specific implants and improve supply chain efficiency through in-house additive manufacturing capabilities.

In September 2024, a major technology company introduced advanced biocompatible materials for healthcare 3D printing applications.

These new materials enhance durability, flexibility, and regulatory compliance, supporting broader adoption of additive manufacturing in medical and surgical applications.

Key Findings of the Study

• Medical implants remain the dominant application segment globally

• North America leads the market due to advanced healthcare infrastructure

• Customization and personalized medicine are key growth drivers

• Rapid advancements in 3D printing technologies support long-term growth

More Info:- https://introspectivemarketresearch.com/reports/healthcare-additive-manufacturing-market/

About Us

At Introspective Market Research Private Limited, we are a forward-thinking research consulting firm committed to driving growth in the Healthcare Additive Manufacturing Market. With deep insights, strategic solutions, and holistic research, we empower businesses to achieve success and dominance in the global healthcare additive manufacturing industry.

📞 Contact Us

Introspective Market Research Pvt. Ltd.

Phone: +91-91753-37569

Email: sales@introspectivemarketresearch.com

Web: www.introspectivemarketresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness