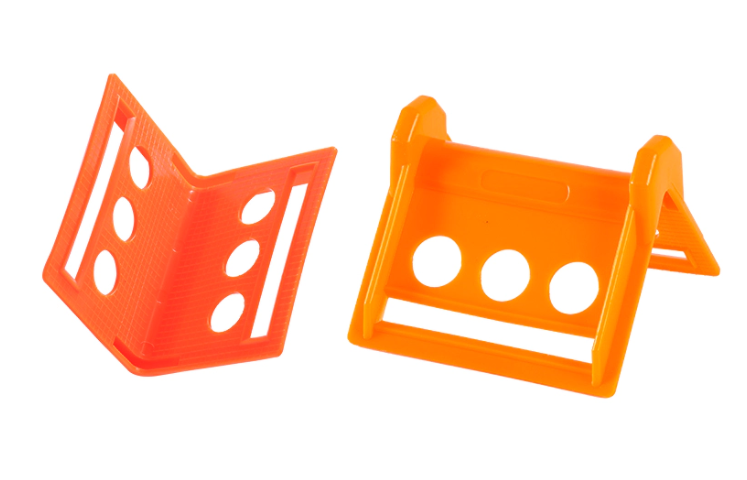

Pallet Rubber Corner Protector: Impact on Warehouse Efficiency

Pallet Rubber Corner Protector is gaining attention in warehouse and transportation operations as companies face shifting demands in load size, stacking density, and shipment complexity. Emerging practices show how these protectors fit into broader efforts to optimize pallet performance and cost-effective shipping workflows.

One emerging trend involves integrating corner protectors into more advanced load-securement systems. For example, robotics and automated palletizers now handle greater volumes and varied load forms. A well-fitted pallet rubber corner protector ensures the automated equipment can apply straps and wraps with less manual adjustment, reducing cycle times and improving load accuracy. In this setting, the protector supports both machine compatibility and securement quality.

Another operational trend centers on stacking height and load optimization in high-bay warehouses. Higher stacks impose more corner and edge pressure, raising the risk of load failure. A pallet rubber corner protector helps distribute strap tension and minimize edge damage under stack-pressure conditions. This enables organizations to push stacking metrics while managing damage risk and maintaining worker safety standards.

In conclusion, the pallet rubber corner protector is emerging as a meaningful driver for warehouse and fleet operators. Through improved load stability, machine-friendly designs, and damage-control benefits, it contributes to more reliable logistics performance and cost management.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness