Global Plastic Straps Market Forecast: Trends to Watch by 2031

The global packaging and logistics industry is evolving rapidly, and plastic strapping solutions are quietly becoming a backbone of safe, efficient, and cost-effective material handling. The Plastic Straps Market is gaining steady traction as industries prioritize load security, lightweight packaging materials, and operational efficiency across supply chains.

Plastic Straps Market Overview

The Plastic Straps Market includes strapping solutions manufactured using advanced polymer materials designed to provide tensile strength and secure load integrity. These straps are available in multiple formats to meet varying load requirements and application needs.

Growing emphasis on supply chain optimization, cost control, and packaging safety has elevated the importance of plastic strapping solutions. Manufacturers are also focusing on material innovation and recyclability, aligning product development with global sustainability goals.

👉 Access Report for More Info: https://www.theinsightpartners.com/sample/TIPMC00002279

Key Market Trends

• Increasing use of plastic straps in automated packaging lines

• Rising focus on recyclable and eco-friendly strapping materials

• Growing preference for lightweight packaging solutions

• Expansion of e-commerce and warehouse operations

Market Analysis

• Demand is shifting toward high-performance straps that balance strength and flexibility.

• Manufacturers are optimizing production processes to enhance consistency and reduce material waste.

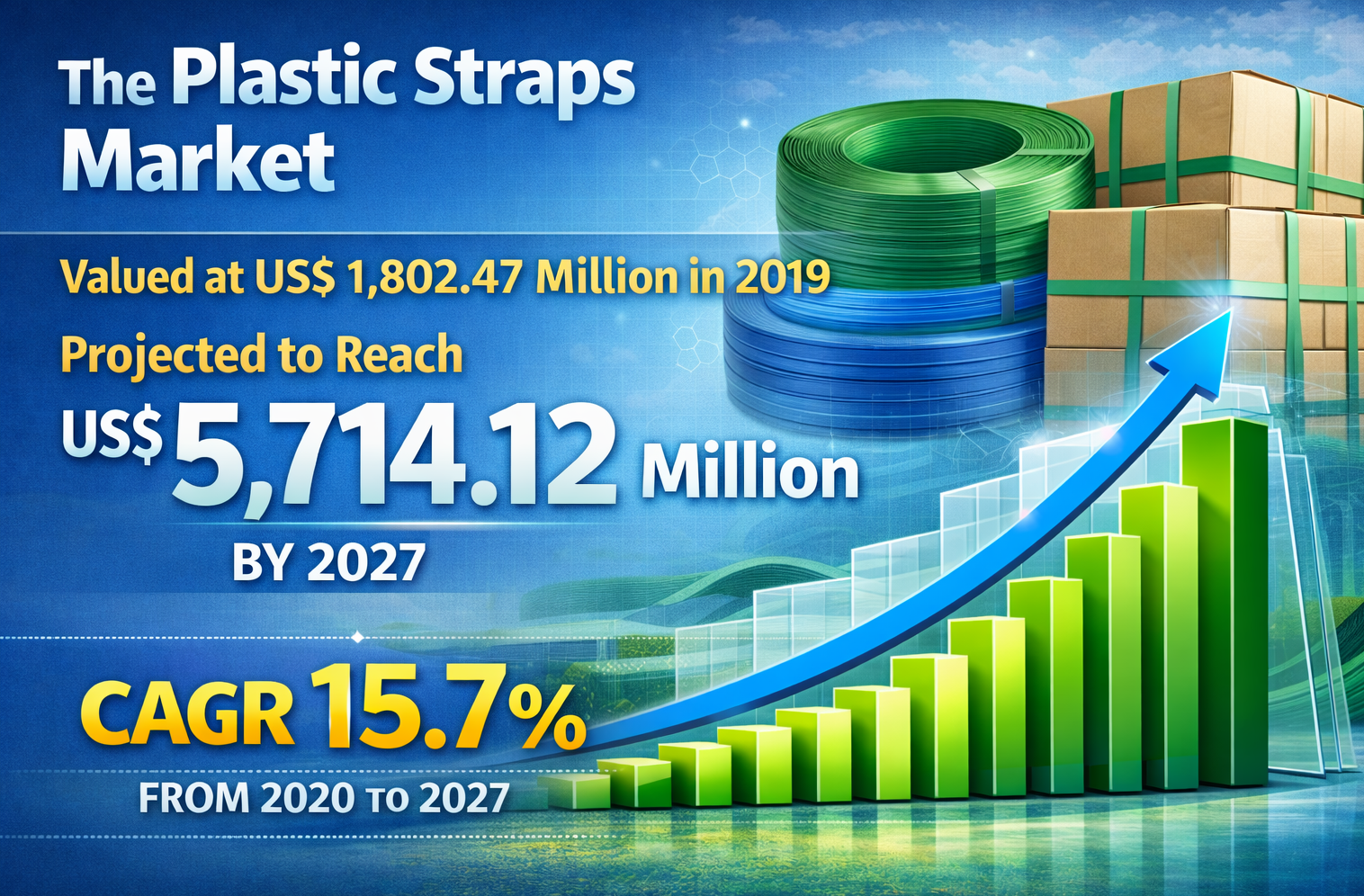

Market Forecast

• The Plastic Straps Market is expected to maintain stable momentum through 2031, supported by logistics growth and packaging modernization.

Global and Regional Analysis

Global Market Landscape

Globally, the Plastic Straps Market benefits from expanding trade activities and the modernization of packaging infrastructure. Industries are increasingly investing in efficient load-securing solutions to minimize transit damage and operational downtime.

The rise of e-commerce has significantly increased demand for reliable and efficient strapping solutions.

Market Players and Competitive Landscape

The Plastic Straps Market features a competitive environment where companies focus on innovation, product customization, and geographic expansion. Key market players are investing in advanced extrusion technologies and sustainable material sourcing to strengthen their market position.

Competitive strategies include:

• Development of recyclable and eco-friendly plastic straps

• Expansion of production capacity

• Partnerships with logistics and packaging solution providers

• Focus on automated strapping system compatibility

Updated Market News and Industry Developments

Recent industry developments highlight growing attention toward sustainable packaging solutions. Regulatory focus on waste reduction and recycling has encouraged manufacturers to redesign plastic straps using environmentally responsible materials. Additionally, logistics companies are upgrading to automated strapping systems, supporting consistent demand for standardized plastic straps.

Future Outlook

The Plastic Straps Market is expected to remain resilient as industries continue to modernize packaging and logistics operations. Sustainability initiatives, automation, and global trade expansion will remain central to market development through 2031. Companies that prioritize innovation and environmental responsibility are likely to gain a competitive edge in the evolving market landscape.

About Us: -

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Also Available in : Korean German Japanese French Chinese Italian Spanish

The global packaging and logistics industry is evolving rapidly, and plastic strapping solutions are quietly becoming a backbone of safe, efficient, and cost-effective material handling. The Plastic Straps Market is gaining steady traction as industries prioritize load security, lightweight packaging materials, and operational efficiency across supply chains.

Plastic Straps Market Overview

The Plastic Straps Market includes strapping solutions manufactured using advanced polymer materials designed to provide tensile strength and secure load integrity. These straps are available in multiple formats to meet varying load requirements and application needs.

Growing emphasis on supply chain optimization, cost control, and packaging safety has elevated the importance of plastic strapping solutions. Manufacturers are also focusing on material innovation and recyclability, aligning product development with global sustainability goals.

👉 Access Report for More Info: https://www.theinsightpartners.com/sample/TIPMC00002279

Key Market Trends

• Increasing use of plastic straps in automated packaging lines

• Rising focus on recyclable and eco-friendly strapping materials

• Growing preference for lightweight packaging solutions

• Expansion of e-commerce and warehouse operations

Market Analysis

• Demand is shifting toward high-performance straps that balance strength and flexibility.

• Manufacturers are optimizing production processes to enhance consistency and reduce material waste.

Market Forecast

• The Plastic Straps Market is expected to maintain stable momentum through 2031, supported by logistics growth and packaging modernization.

Global and Regional Analysis

Global Market Landscape

Globally, the Plastic Straps Market benefits from expanding trade activities and the modernization of packaging infrastructure. Industries are increasingly investing in efficient load-securing solutions to minimize transit damage and operational downtime.

The rise of e-commerce has significantly increased demand for reliable and efficient strapping solutions.

Market Players and Competitive Landscape

The Plastic Straps Market features a competitive environment where companies focus on innovation, product customization, and geographic expansion. Key market players are investing in advanced extrusion technologies and sustainable material sourcing to strengthen their market position.

Competitive strategies include:

• Development of recyclable and eco-friendly plastic straps

• Expansion of production capacity

• Partnerships with logistics and packaging solution providers

• Focus on automated strapping system compatibility

Updated Market News and Industry Developments

Recent industry developments highlight growing attention toward sustainable packaging solutions. Regulatory focus on waste reduction and recycling has encouraged manufacturers to redesign plastic straps using environmentally responsible materials. Additionally, logistics companies are upgrading to automated strapping systems, supporting consistent demand for standardized plastic straps.

Future Outlook

The Plastic Straps Market is expected to remain resilient as industries continue to modernize packaging and logistics operations. Sustainability initiatives, automation, and global trade expansion will remain central to market development through 2031. Companies that prioritize innovation and environmental responsibility are likely to gain a competitive edge in the evolving market landscape.

About Us: -

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Also Available in : Korean German Japanese French Chinese Italian Spanish

Global Plastic Straps Market Forecast: Trends to Watch by 2031

The global packaging and logistics industry is evolving rapidly, and plastic strapping solutions are quietly becoming a backbone of safe, efficient, and cost-effective material handling. The Plastic Straps Market is gaining steady traction as industries prioritize load security, lightweight packaging materials, and operational efficiency across supply chains.

Plastic Straps Market Overview

The Plastic Straps Market includes strapping solutions manufactured using advanced polymer materials designed to provide tensile strength and secure load integrity. These straps are available in multiple formats to meet varying load requirements and application needs.

Growing emphasis on supply chain optimization, cost control, and packaging safety has elevated the importance of plastic strapping solutions. Manufacturers are also focusing on material innovation and recyclability, aligning product development with global sustainability goals.

👉 Access Report for More Info: https://www.theinsightpartners.com/sample/TIPMC00002279

Key Market Trends

• Increasing use of plastic straps in automated packaging lines

• Rising focus on recyclable and eco-friendly strapping materials

• Growing preference for lightweight packaging solutions

• Expansion of e-commerce and warehouse operations

Market Analysis

• Demand is shifting toward high-performance straps that balance strength and flexibility.

• Manufacturers are optimizing production processes to enhance consistency and reduce material waste.

Market Forecast

• The Plastic Straps Market is expected to maintain stable momentum through 2031, supported by logistics growth and packaging modernization.

Global and Regional Analysis

Global Market Landscape

Globally, the Plastic Straps Market benefits from expanding trade activities and the modernization of packaging infrastructure. Industries are increasingly investing in efficient load-securing solutions to minimize transit damage and operational downtime.

The rise of e-commerce has significantly increased demand for reliable and efficient strapping solutions.

Market Players and Competitive Landscape

The Plastic Straps Market features a competitive environment where companies focus on innovation, product customization, and geographic expansion. Key market players are investing in advanced extrusion technologies and sustainable material sourcing to strengthen their market position.

Competitive strategies include:

• Development of recyclable and eco-friendly plastic straps

• Expansion of production capacity

• Partnerships with logistics and packaging solution providers

• Focus on automated strapping system compatibility

Updated Market News and Industry Developments

Recent industry developments highlight growing attention toward sustainable packaging solutions. Regulatory focus on waste reduction and recycling has encouraged manufacturers to redesign plastic straps using environmentally responsible materials. Additionally, logistics companies are upgrading to automated strapping systems, supporting consistent demand for standardized plastic straps.

Future Outlook

The Plastic Straps Market is expected to remain resilient as industries continue to modernize packaging and logistics operations. Sustainability initiatives, automation, and global trade expansion will remain central to market development through 2031. Companies that prioritize innovation and environmental responsibility are likely to gain a competitive edge in the evolving market landscape.

About Us: -

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Also Available in : Korean German Japanese French Chinese Italian Spanish